AeroSeries

The Aero Series Advantage

|

Aero® 40FP

Our mid-level machine, the Aero 40FP is a full pressure dry ice cleaning system that includes radial feeding system technology, which provides aerodynamic loading to reduce wear on pads and rotor; utilizes a compact motor that reduces weight and lowers power consumption; includes an enhanced rotor that provides pulse-free blasting and precision feed rate control; and has an onboard pressure regulator. Customized with accessories that will provide the best clean for your environment, the Aero 40FP provides new technology in a proven design. Aero® 80FP

The Aero 80FP is a full pressure dry ice cleaning system that includes radial feeding system technology that is aerodynamic loading to reduce wear on pads and rotor; utilizes a compact motor that reduces weight and lowers power consumption; includes an enhanced rotor that provides pulse-free blasting and precision feed rate control; and has an onboard pressure regulator. Customized with accessories that will provide the best clean for your environment, the Aero 80FP provides premium technology in a proven design. |

i³MicroClean2

The i³ MicroClean 2 Advantage

|

The i³ MicroClean® 2

The i³ MicroClean 2 is the next generation of precision cleaning offering more power, better efficiency, intuitive controls, and IoT capabilities to our most precise line of dry ice blasters, all in a lightweight, compact, and single-hose blasting system.

The i³ MicroClean 2 boosts performance and reduces overall consumable usage by more than 25% over its predecessor. This machine utilizes dry ice block or pellets and can operate with as little as 12 cfm (0.3 m³ /min) at variable air pressures from 20 to 145 psi (1.4 – 10 bar).

With a 7” LCD screen and digital controls, the i³ MicroClean 2 provides an intuitive display that allows the user to easily view and adjust blasting parameters and machine settings. This powerful dry ice blaster also features programmable application recipes, which allows users to set and save blasting parameters, such as blast pressure and feed rate.

The i³ MicroClean 2 is IoT enabled via Cold Jet’s Industry 4.0 solution, Cold Jet CONNECT®. The system provides remote monitoring and diagnostics. |

Aero2®Series

The Aero₂ Series Advantage

|

The Aero2® PCS 60

Designed to give the user complete control. Utilizing Cold Jet’s Particle Control System™ (PCS), dry ice is cut into diamond shaped particles in the exact dimensions chosen by the operator (0.3mm to 3mm and every size in between), allowing the user to fine-tune blasting parameters for each unique application.

With a 7" LCD screen and digital controls, the PCS 60 provides an intuitive display that allows the user to easily view and adjust blasting parameters and machine settings. The machine also features programmable application recipes, which allows users to set and save blasting parameters, such as blast pressure, particle size and feed rate.

The PCS 60 is IoT enabled via Cold Jet's Industry 4.0 solution, Cold Jet CONNECT®. The system provides remote monitoring and diagnostics. The Aero2® PLT 60 Building upon the groundbreaking Aero2 technology, the PLT 60 is designed for applications that require more aggression. With PLT machines, you can blast with up to 250 PSI (17.2 bar) of pressure using proprietary nozzles that are optimized for high performance.

The PLT 60 utilizes Aero advancements that enable the machines to be the most efficient dry ice blasters available. With a ‘straight through’ air system and redesigned SureFlow™ feeding system, air pressure loss and dry ice sublimation are minimized within the machine. This allows the user to maximize air supply yield and reduce dry ice waste.

With a 7” LCD screen and digital controls, the PLT 60 provides an intuitive display that allows the user to easily view and adjust blasting parameters and machine settings. The machine also features programmable application recipes, which allows users to set and save blasting parameters, such as blast pressure and feed rate.

The PLT 60 is IoT enabled via Cold Jet’s Industry 4.0 solution, Cold Jet CONNECT®. The system provides remote monitoring and diagnostics. |

I3Microclean

I3 Micro clean This unique cleaning system capitalizes on Cold Jet’s patented shaved ice and feeder tech-nologies to deliver a complete precision cleaning solution. It is an ergonomic and intuitive system that utilizes a readily available blast medium, and is fast, effective and proven reli-able. Furthermore, unlike any other blast system available today, its unparalleled low air and ice consumption provides for cost-effective operation in an almost noise-free environment.

|

Enhanced Blast ApplicatorLightweight, ergonomic design with mobile head enabling blasting at various angles. LED lights on applicator face light up dark surfaces being cleaned. Safety switch. Standard Blast Applicator

|

IceTechSeries

The IceTech Series Advantage

|

IceTech® Xcel 6

Evolve the way you clean your equipment with the enhanced Xcel 6. Designed with advanced operating principles, the Xcel 6 maintains a smooth cleaning performance while enhancing dosing disc operation. With a small footprint and a stainless steel frame, the Xcel 6 is designed to provide a reliable cleaning solution with minimal air requirements. IceTech® Elite 20

The Elite 20 is a versatile, heavy duty dry ice blaster that can be used for light, medium up to tough applications with low dry ice consumption. With 3/4” blasting hose, the Elite 20 is an ideal solution for cleaning more demanding surfaces.

Dry ice blasting machines and accessories are designed to minimize the costs of equipment and plant maintenance. When using dry ice blasting it is possible to clean devices online, without any dismantling and subsequent reassembly. Production downtime can be avoided or reduced drastically, supporting an economical approach to facility maintenance. |

Xtreme40

The Xtreme 40

What makes the Evolution Line different? The Evolution Line provides the perfect universal dry ice blasting experience. New, quick change dosing disc allows for a faster replacement, which leads to shorter downtime and lower maintenance costs. The insulated lid and hopper helps eliminate clumping of the dry ice, and provides troublefree blasting. The stainless steel frame provides a high strength, scratch-resistant machine designed to keep up with the toughest conditions, while still suitable for lighter applications like those found in the food and pharmaceutical industries. |

Xtreme 40 SPECIFICATIONS

|

Elite20

The Elite 20

Evolve the way you clean your equipment with the world’s first multi-power dry ice blasting machine! The Elite 20 contains a 24 volts DC motor that utilizes a higher torque to eliminate freeze ups. From the complete control over ice and air consumption to the worry free troubleshooting, the Elite 20 provides a dry ice blasting experience that is divergent in the industry.

|

Elite 20 SPECIFICATIONS

|

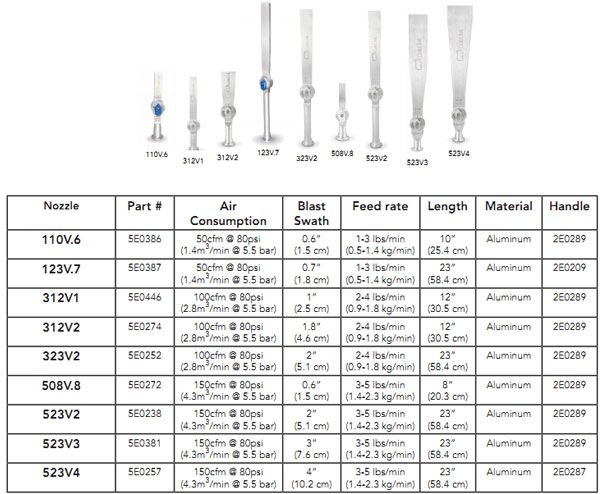

Nozzles

Aero NozzlesCold Jet’s Aero nozzles are designed to maximize performance whatever the application. Broad or precise cleaning, hard to reach areas or working in a confined space, our line of nozzles will exceed your expectations. Recommended operating parameters are shown in the tables for each nozzle. Nozzles noted with (*) are recommended for use where blasting pressure is >140 psi (9.7 bar). Recommended accessory handle is noted where applicable. Low and Standard Flow NozzlesThese straight nozzles have standard air consumption rate of 100 cfm or less at 80 psi.

|

High Flow NozzlesThese straight nozzles have air consumption rate of more than 100 cfm at 80 psi.

|

Variable Fragmenting MERN NozzlesWith patented MERN technology and new variable fragmenting technology you have the power to control aggression downstream of the nozzle throat for a full range of performance with maximum effectiveness - the most ever from a single nozzle.

|

Specialty NozzlesThese nozzles have various configurations for special applications and operate with air consumption rates as noted.

|

Nozzle Extension TubesExtension tubes are used to extend nozzles when additional reach is needed with minimal pressure loss. Extension tubes connect to nozzle and applicator with proper fittings (not included).

|

Nozzle AccessoriesExtension tubes are used to extend nozzles when additional reach is needed with minimal pressure loss. Extension tubes connect to nozzle and applicator with proper fittings (not included).

|

Applicators

|

Blast Hose** One corresponding Bond Cable Shaft Collar is required per complete hose run (not one per section)

|

Hoses, Cables and Connectors

|

Hoses, Cables and Connectors

|

Filters and Regulators

|

- 首页

- 上一页

- 1

- 下一页

- 末页